Do you need Towels in Bulk??

With 100% Cotton or Bamboo

Do you need your own Designs and Colors?

[ We are Producing since 2002 ]

We deliver all over the world (FOB, CIF, Door Delivery)

We are manufacturing 100% Cotton and Bamboo Terry Bath Towels, Beach Towels, Wash Mitts, Bathrobes Anti Bacterial Anti Viral Silver Towels and Baby Towels since 2002.

Browse through the categories or

READ HERE For initial details about production MOQ, designs, packaging and delivery options. Please go through it for deeper understanding

Bath Towels:

OekoTex 100 Standard Towels, GOTS Towels (Global Organic Textile Standard) , GRS Towels (Global Recycle Standard) and RCS Towels (Recycle Claim Standard) are available

What is a Velour Towel?

Velour is a processed form of terry that is softer and a feel like velvet. Terry loops are cut, brushed & polished in a process that is called shearing. In a terry towel, you can see the terry loops separately however, in velour towel, cotton terry fibers are fine and thin like a head full of hairs, you can feel but cannot see or count a single fiber separately.

What is a Hotel Towel?

A Hotel Towel is more durable than a normal household towel. Hotels and Restaurants wash the towels daily in commercial laundries. To withstand continuous washing in high temperatures with chlorine, a different, more durable , more expensive quality of yarn is used. Softness of towels of 2-3 star and 5-star hotels is different as they have different levels of budget allocation for this article

Beach Towels

Zero Twist Towels

Recycled Towels

Organic Cotton Towels

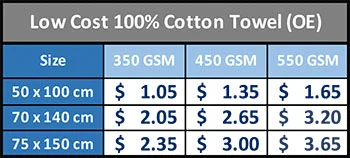

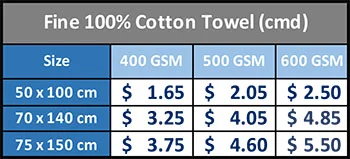

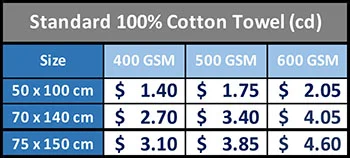

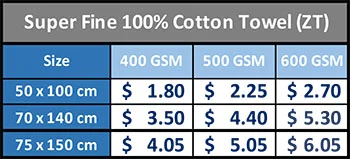

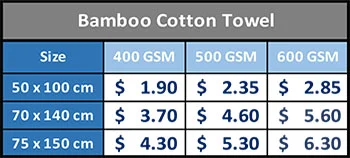

Towels Price List

- Prices are calculated in September 2021 for a quantity of 20 FCL. Which contains 7000-8000 Bath Towels. Lower quantities will cost a little more.

- Prices are FOB Karachi, Pakistan

- Customized packaging will cost additional

- Standard Prices are for Calculation Purpose. Final prices may vary a little after sampling and quantity decision

- Door Delivery (DDU or DDP) Prices can be offered as well

For calculation purpose: 2000 Bath Towels will cost 2000 USD to be delivered in EU or USA

20 FCL will cost 3000 USD to be delivered in EU or USA - There is 0% Import Duty in EU and 6% Import Duty in USA, for Towels from Pakistan

- All Towels are Oeko-Tex 100 certified. GOTS Organic, GRS Recycled Towels are also available

Bath Gloves:

How a Towel is Produced?

Towel manufacturing is a little different than standard woven fabric. Instead of two yarns (Warp and Weft), a third yarn is also used that makes the terry loop of the towel. These Terry Loops actually define the quality of the towel. Water absorbency and softness both depends upon this terry towel pile/terry.

What makes the quality of a Bath Towel?

A towels quality is measured with its Absorbency and Softness. There are several aspects that affects the quality.

1- Yarn:

In towel manufacturing, yarn is the most important thing for quality as well as price. From low cost thick single yarns to fine quality double yarns, there are many qualities. Besides the thickness (Yarn Count), Yarns quality is actually the cotton’s quality that is used to produce yarn. Low quality cotton including waste cotton is used to produce low-cost yarns, whereas the finest cotton is used to produce a fine yarn that is expensive as well. Regardless of the kind of cotton (Egyptian, Pima, Pakistani or Turkish cotton) the selected quality of cotton is important.

Egyptian Cotton is softer and more expensive than other regular cottons. PIMA cotton is softer and more expensive than even Egyptian cotton.

Bamboo is also used to produce towels. BAMBOO is BEST. Its softness, absorbency and durability is far greater than cotton. It is antibacterial and hypoallergenic. It is expensive.

There are three yarns in a towel, two of them make the ground of towel and the 3rd most important one makes the pile/terry of towel. Lower quality can be used for the ground but the pile or terry should be of good quality to improve the quality of the towel. Especially the fabric that is produced for Cotton Terry Bathrobes, where you don’t see the ground yarns nor they have any effect on absorbency, the 3rd yarn is the most important. It doesn’t matter where the towel is being produced, either in Pakistan or in China, in India, in Turkey or elsewhere, the use of yarn determines the class of towel. Use of double yarn in pile increases the look as double yarns keep standing even after dyeing or washing. Double yarns are used especially for jacquard towel designs. A firmly standing terry loop can make a sharper edge of a design or text on a towel.

There are hundreds of qualities and several counts of towel yarns; you can produce 1000s of different qualities of towels by different yarn combinations.

With the experience of 20 years and high investment on research and learning, we have shortlisted some yarns and qualities, for specific target markets. Read Below for a summarize look. You may ask for samples of each quality and select as per your choice.

For Low-Cost Bath Towels bulk wholesale and Institutional use: Z1-Autocoro Yarn Cotton Towels

For low-cost bulk wholesale, Institutional use and Low-cost Bathrobes; with increased absorbency and softness. Almost 50% Towels in the world are made with this quality. Towels For 3-4 Star hotels Wholesale. Beach Towels and Pool Towels are also suitable in this quality: Z2-Carded Ring Cotton Towels

For Brands, selling to consumers who are willing to pay some extra bucks for quality. For 5 Star hotels, Spa Golf Towels in Bulk: Z4-Combed Cotton Towels

Only for quality conscious consumers. More soft and less durable than above mentioned qualities: Z5-Zero Twist Cotton Towels

For High end brands and consumers who always search for extra quality & For Gym Towels: Z6-Bamboo Towels

Within these qualities, we can produce different weights and we can use different count of yarns as per the usage and budget restrictions.

16s and 20/s are the most common yarn counts for towel’s pile/terry loop. However, 10s, 12s and 30/2 are also used.

Even with an in-depth knowledge, You cannot describe and decide the quality of a towel in words. You must check the samples even before asking for prices from a manufacturer or a wholesaler.

2-Weight of Towel:

All those above qualities can be produced from 250 gsm (gram per square meter) to 1200 gsm. Price and absorbency increase with the weight of a towel. Price almost increases pro rata. Heavyweight towels feel luxurious and absorb much more water however, deciding the weight of towels depends upon the paying capacity of your target audience. Heavy weight towel also give margin to use thick (but higher quality & softer) yarns. Thick yarns give a plusher feeling and look.

3- Dyeing of Towels:

Dyeing determines the safety of towels as well as washing ability. There are several techniques of dyeing being used. Use of harmful substances is strictly discouraged to avoid health and environment issues, so take care to ask for Reactive or Vat dyeing (especially Oekotex Standard 100 Class 1 certified dyeing) while negotiating a deal with your manufacturer in Pakistan, in India or in Turkey. Usually, towels are washed at 50-60 degrees warm water however, hotel and hospital towels are washed in commercial laundries at high temperatures with chlorine (to remove stains and kill bacteria). Only Indanthrene dyes can withstand such washing processes and they don’t lose their colors even after 100s of washes.

We can dye the towel in any color. select from Color Chart.

Does the color or printing affect the absorbency of Towel?

White is the most absorbent; dark colors have a little lesser absorbency than light colors. Regarding printing, NEVER go for it for towels. Printing affects the absorbency and softness of towels. Regardless of the printing method, It reduces the capacity to absorb water to a great extent. Instead, you may go for Embroideries or yarn dyed patterns.

Can you do Embroidery on a Towel?

Embroidery gives an elegant and personalized look to the towel. Keep the embroidery small. Yes, we can do all types of embroideries on our towels.

What type of Packaging is best for Towels?

Packaging always adds worth to the product. Select from our collection of Plastic bags, RPET recycled bags, and Cardboard box packaging styles; customize it OR design your Own. Packaging must be designed keeping in mind the budget and requirements of storage. You can save several bucks on storage costs.

What is a Jacquard Towel?

What is the difference between a Dobby and Jacquard Towel?

A Jacquard Towel is a towel in which design is weaved into the fabric. The design can be a text, a logo or a picture. Design can have the same color as the towel (means the whole towel will be a single solid color towel) or different colors can be used for the design. In case of several colors, the yarn is dyed before weaving and then the towel is weaved (in case of single color, towel is dyed after weaving). Yarn dyeing is far more expensive than the finished fabric dyeing; hence, a several color jacquard towel is more expensive than a single color Jacquard Towel. Jacquard initial set up cost is also higher.

Jacquard is a machine that is used to produce this type of towels.

Dobby is also a machine that is used for the same purpose, however, for simpler designs. Dobby is usually used for the border of towel or for weaving simple logos or simple text into the towel. Different colors can be used with dobby as well. Traditionally, Greek border is produce with Dobby. Such towels are called Dobby Towels.

In Short, Jacquard is used for complex designs and Dobby is used for simple designs.

What is a Gym Towel?

What is a Silver Ion Anti-bacterial Towel?