How to Design Packaging of Your Product Yourself, Improving Sale & Safety

Bulk Packing

Retail Packing

Bulk packing is done by packing the product directly into master cartons with only one master poly bag. Minimum packaging is involved. It is usually for institutional use e.g. Hospitals & Hotels; where the goods are supposed to be used and don’t required individual packs.

Retail packing is meant to present the goods to a retail consumer, individually; safety of the goods and appropriate presentation is the purpose of packing. It involves or may involve several packaging materials.

1-Plastic Bags:

PP bags are lowest cost, incredibly strong and flexible, however, they tear down easily even with a single prick. They are not tear-resistant nor stretchable

These bags are a little expensive than PP bags but cheaper than card boards, paper boards and other natural materials. They are proved durable than PP Bags

Polypropylene Bags

Polyethylene Bags

If you sell products that do not require protective measures, the price may be the deciding factor in favor of PP. PE is generally more expensive due to the purity of the material and the protection it provides.

With these two materials, we can produce different styles of bags. Bag size depends upon the product size; however, closure style may change. We can use simple closing with additional adhesive tape, self-adhesive tape, zipper closure, or snap buttons. Bottom or side gussets (depth) can be planned for proper fitting.

These bags can be printed upon demand. There may be only care instruction or the branding material also be there.

Printed craft paper may be packed inside, instead of printing the plastic bag. These paper are packed inside the bag with printed face outside.

Stiffener cards may be used to give the packaging dimensional stability.

These plastic bags are not biodegradable, therefore, if you are planning an environment friendly product line, you must consider below mentioned board boxes that are made of all natural, biodegradable and environment friendly materials.

How Important Is Eco-Friendly Packaging?

2-Board boxes:

Board boxes are of two types. Paperboard and cardboard. Both are made of renewable plants/crops materials and Mother Earth happily allows their usage.

Paper board boxes are made with paper of different qualities and thicknesses. We use the best craft papers made of virgin material in thicknesses ranging from 200-450 gsm.

The selection of material depends upon the budget.

.

.

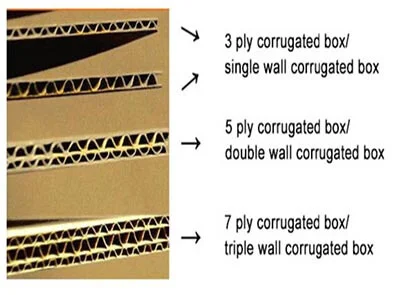

Cardboard boxes are made of 3 ply card (2 Kraft paper cards and a corrugated card in between). These cards are available in waste and virgin materials. Virgin materials are somewhat expensive than waste materials. Waste cards are heavier as higher thickness is used to provide required strength.

There are different styles of boxes. You may select one according to the product, stacking and marketing requirement. Please use reference numbers of these style to communicate with us

The size of the box is carefully decided to keep in mind the courier charges and shipping/stacking requirements, to keep the charges as low as possible.

3-Fabric Bags:

Some bedding and clothing brands sometimes go for a bag that is made of the same fabric as bedding. This is expensive; however, it lets the consumer feel the fabric without opening it.

4-Master cartons:

Above mentioned all packaging materials are used to enhance the presentation and to keep the product safe and clean. Master cartons are used to transport the products from the manufacturer to retail outlets.

These cartons are made of 3-5-7 ply cardboard (with craft paper and corrugated board). Their design and size depend upon the maximum lifting capacity, stacking/space requirement in warehouses, pallets and containers. Most of the new brands usually follow Amazon Instructions regarding size and weight of these cartons. They must be strong enough to deliver product retail boxes safely to the end seller.

These cartons are labeled with Company Name, order reference #, product details, and quantity per box.