How to search a manufacturing partner in textile world

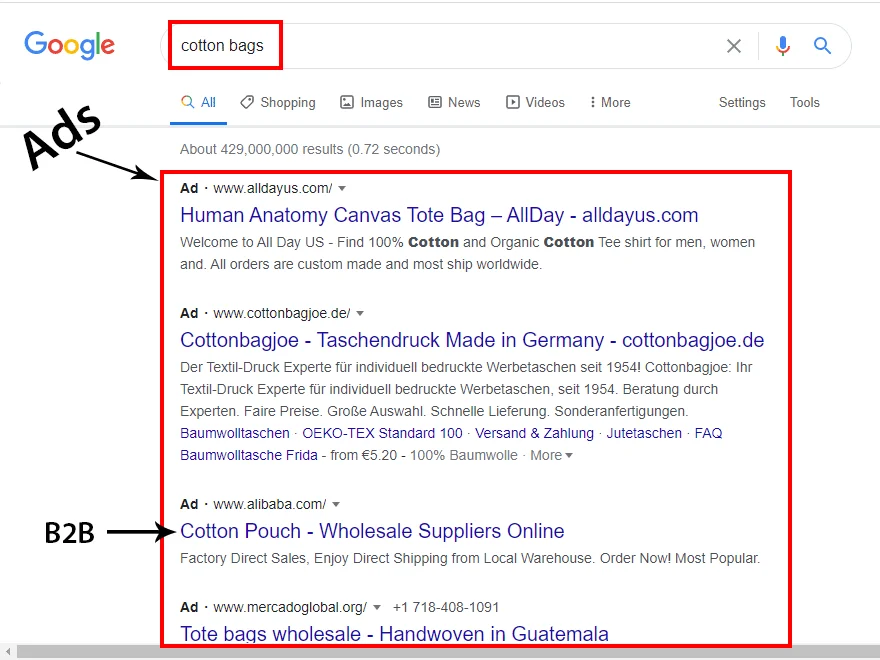

The initial search for a manufacturing partner begins with web browsing. 1st pages of google are usually populated with Ads of online stores, and B2B platforms

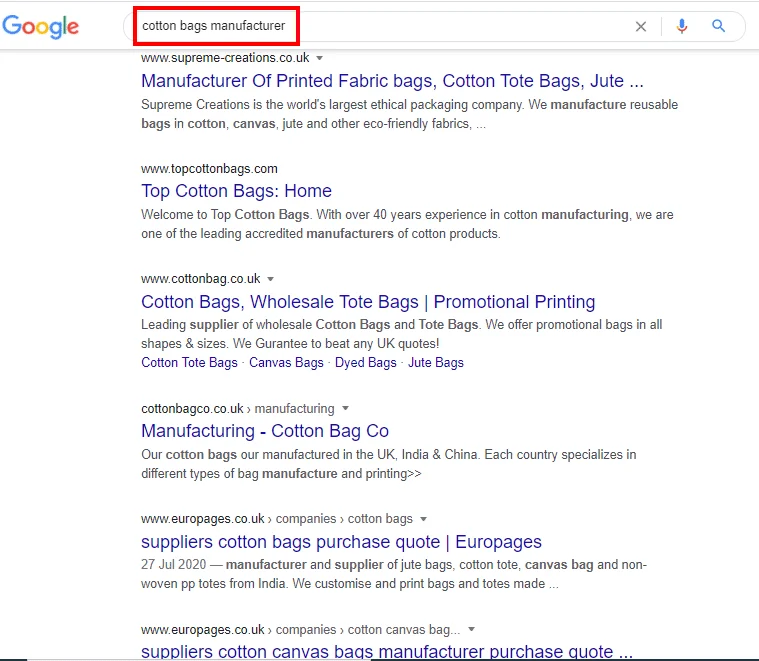

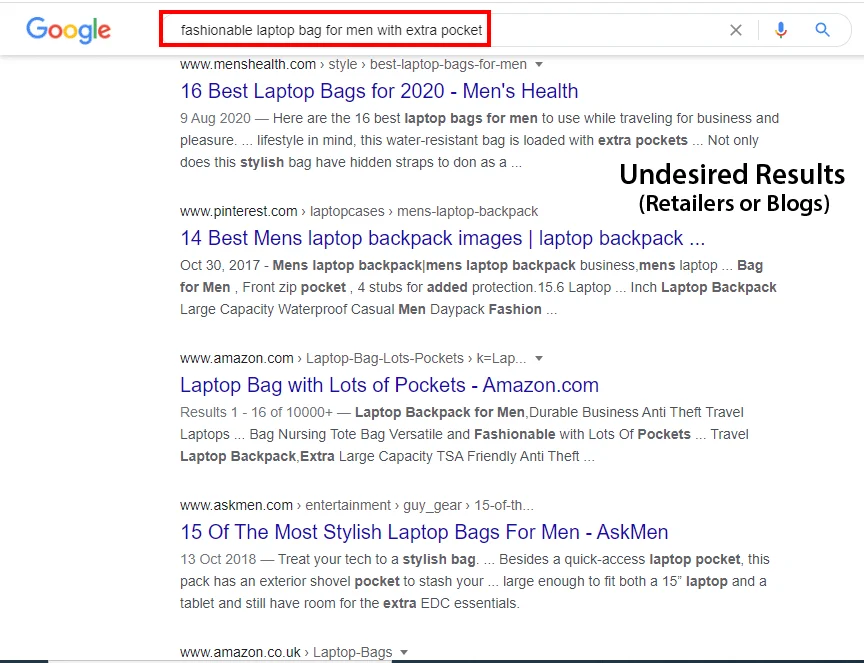

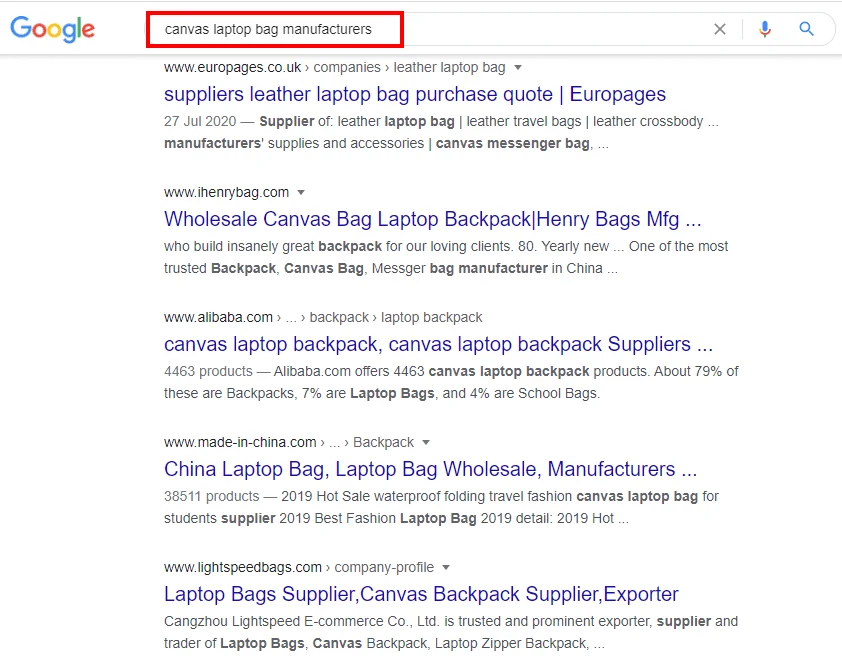

You can rarely find a manufacturer on 1st pages, however, if there is any, he must be among your 1st choices as he usually understands the requirements of the present day. Otherwise, sort out manufacturers from B2B websites and Online Retail Stores. You can easily find out who is a manufacturer. They usually don’t display prices online, as they are producing customized products and cost calculations are different for each article. They usually don’t have a sign-in option. They display and tell more about their capacity than their products. The search engine result snippet usually have details of manufacturing, production, machinery, working since, location and certifications. Retailers snippets shows aspects/details of product instead.

The manufacturer of choice must have at least 10 years’ experience in contract manufacturing. Look for certificates they possess. Product / Company certifications like Oekotex 100 and ISO 9001 increase the authenticity of your partner. Don’t ask for their details initially, check online. Check their company’s age and their website age. Check their online presence; membership of large online platforms can help understand them.

Check their Google page or check them on Google Maps. Check how many likes/comments they have. Manipulating likes and comments is possible when they are in dozens. It isn’t possible to manage or fabricate them when comments are in hundreds or thousands. 100s or 1000s of likes and comments actually authenticate them, at least as a real working manufacturer with engagement from clients and staff.

Study about your product before contacting them, so you may have sufficient data to discuss and a little understanding of technical terms and available options. Study their website to understand what they are doing and what they can do. Good manufacturers mention initial details on their sites to avoid unnecessary contacts. They usually don’t have huge customer relations / call center teams as they have a limited number of customers.

Most important is your contact person; who must have a comprehensive understanding of materials and the production processes. He/she must be available and ready to discuss each and every aspect. Developing a new product needs long discussions and that can’t be done if they are not replying in hours (not in days). There is a time difference between countries and delayed answers can cost whole days and weeks. Assess if the person on the other side is actually your concerned person or just a call center guy with limited technical knowledge. You must discuss things with a relevant person.

The next step is to share your required specifications in detail. Effective Communication is the key to a successful business. Communicating your requirements enables them to focus on specific details. Share your previous problems with fabric, design, finishing, packaging, and delivery, so they may avoid. If you still haven’t selected a specific product then select some items from their website or from any other manufacturer’s website; share the details with them so they may evaluate the textile/garment and suggest options. Remember, finished textile or garments articles consists of a lot of raw materials and processings. Garments factories or textile mills don’t do all by themselves. They outsource many services. Give them space so they may share which aspects are being outsourced. Don’t expect a factory to produce the whole product including zippers and poly bags and cartons all by themselves.

Negotiate prices keeping the quality in mind. Manufacturers keep a standard profit margin. Lowering the prices beyond the minimum can risk quality. Remember, quality can bring you customer satisfaction which boils down to more business. Lower prices can bring you a little more profit margin but not the higher sales. Experienced and talented manufacturers usually have higher prices however, their services justify that.

Usually, Pakistan, India, Bangladesh, and Vietnam have similar prices; everyone among them has their own comparative advantage. China is getting expensive but still getting good business due to its established relations, infrastructure, and the supporting industry. Look for recent developments while selecting the manufacturer. You may go for Pakistan; due to current currency devaluation @ 30%, Pakistani products are enjoying matchless price competitiveness. GSP plus also entitles them to tax-free import in the European Union. COVID-19 crisis has also crippled the industry of some of the large textile manufacturing countries including China and India. Select accordingly to avoid unnecessary delays and problems.

Payment for samples should be done with regular banking channel or through renowned payment gateways like PayPal and Alipay. Ask for a same company name bank account, or a PayPal with same email address. Remember, some countries don’t have PayPal and Alipay however they are good at manufacturing.

B2B platforms usually asks to keep the deal through them however, it usually don’t serve the purpose. Alibaba have registered suppliers from all over the world but their Trade Assurance Service and other related risk management mechanisms are for Chinese suppliers only.(until today). This type of restrictions are not mentioned usually in their own guidelines. Spend your energies on initial selection and investigation so you may deal confidently. Risk management through Escrow payments or through B2B platforms may save your payment but cannot save your business. Your business depends on great quality and in time deliveries, not on getting refunds for faulty goods.

Keep all communication concerning one article in a single email thread, to follow it easily. Bring everything into writing when you have finalized all terms. Keep the detail as simple as possible for easy follow up.

Ask for real time status of your production. Don’t wait for the deadline. Keep a check on given deadlines of production process. This way you can ensure that the manufacturing is on its scheduled plan. Ask for their schedule OR use the Production Scheduling Template. Customize it according to your own details.

After receiving and selling your goods, must give feedback to your supplier. Feedback should be swift to improve the product in next production.

Hammad Haseeb-October 25, 2020