Do you need Jersey Knit Sheets in Bulk?

We are Producing Knit Bed Sheets & Crib Sheets with 100% Cotton, Bamboo, Polyester and Spandex

Single Jersey, Double Jersey, Honey Comb, Pop Corn and Plaited Knits are available

[ We are Producing since 2002 ]

We deliver all over the world (FOB, CIF, Door Delivery)

READ HERE For initial details about production MOQ, fabrics, colors, printing, designs, packaging and delivery options. Please go through it for deeper understanding

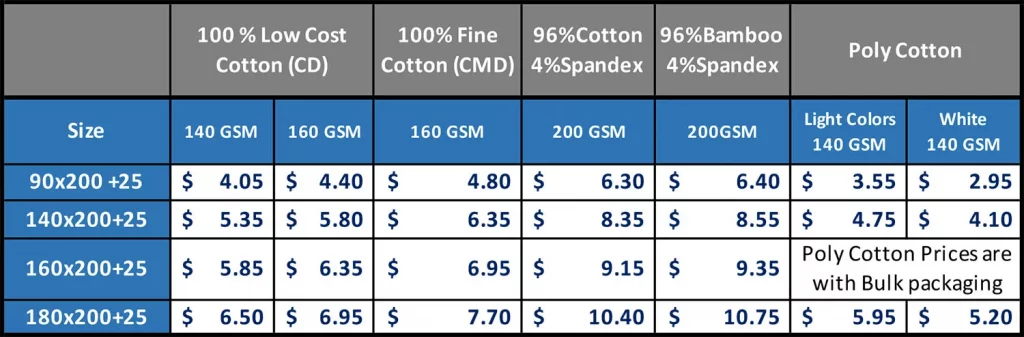

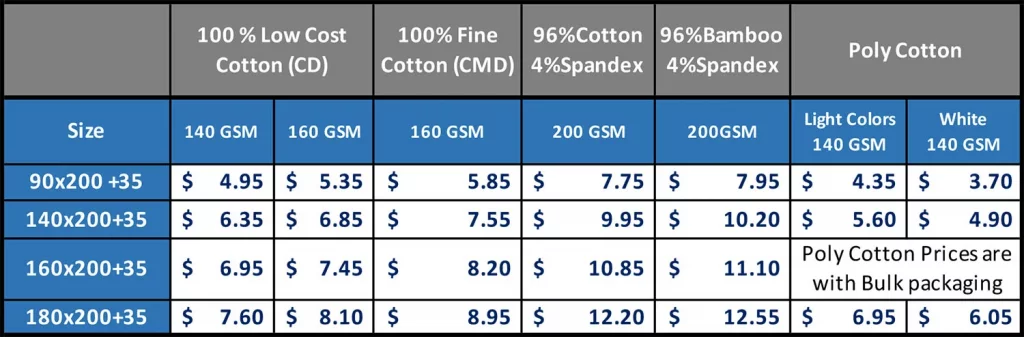

Jersey Fitted Sheets Price List

- Prices are calculated in September 2021 for a quantity of 20 FCL , contact us for latest prices. Lesser quantities will cost a little more. There are around 4000

- Fitted Sheets (retail Packaging) and 12000 Fitted Sheets (bulk packaging) in a 20 Feet Container.

- Prices are FOB Karachi, Pakistan

- Customized packaging will cost additional

- Standard prices are for calculation purpose. Final prices may vary a little after sampling and quantity decision

- Door Delivery (DDU or DDP) prices can be offered as well. For calculation purpose: 1000 Fitted sheets will cost 1500 USD to be delivered in EU or USA. 20 FCL will cost 3000 USD to be delivered in EU or USA

- There is 0% Import Duty in EU and 6% Import Duty in USA, for fitted sheets from Pakistan

STEPS TO CREATE A PRIVATE LABEL HOT SELLING BED SHEET

Details of fabric:

Use of Jersey in the manufacturing of bedsheets is rapidly growing, courtesy to its characteristics. Jersey is softer than woven fabrics and it is highly stretchable. Stretchability makes it the best for bedding. You do not need to worry about wrinkles neither you have to make the bed again and again. This makes it user friendly, looks excellent and the feel soft.

Jersey can be produced with different materials. Cotton, Polyester, Bamboo; and their blends with spandex, in weights ranging 120-300 gsm. To make it easy, we will discuss it in parts.

Materials:

1-Cotton: is considered the best for textile items that have a direct contact with skin. There are several types of yarns that can be used to produce Jersey. From low cost standard cotton to finest combed cotton, from thick yarns to thin yarns. Characteristics remain same for all yarns, however; improve with the quality of yarn, especially the feeling. Low cost yarns have a rough feel which turns into softness and silkiness as the quality increases. Price increases with the quality

2-Bamboo; The Best: exhibits the same characteristics as cotton, but to a higher extent. It is Softer, silkier, have drapery, more durable than cotton. It is anti-bacterial and hypoallergenic. It produces highest quality bedding. However, it is expensive, but it is worth spending. We Love it.

3-Polyester: Polyester is best for look and durability. It doesn’t change shape or lose its color even after hundreds of washes. It produces a silky look; and it is low cost than Cotton and bamboo.

Use of spandex: It is also called Lycra Or Elastane.

Jersey is stretchable however, blending of spandex with basic material increases its stretch-ability. Spandex is an elastic meant to be used in fabrics with basic yarns. Spandex is used in a range of 3% to 14%. More spandex, more elasticity. It helps retain the shape. Higher spandex ratio sheets can be used for different sizes of mattresses, thanks to its improved elasticity. Spandex is expensive than basic materials i.e. cotton, polyester, bamboo.

Weight-GSM (grams per square meter):

Jersey bed sheets are produced from 120 to 300 gsm. Selection of weight purely depends upon price range and the audience you are targeting. Weight translates into consumption of basic material. Higher weight, higher consumption, higher prices. 120-140-160 gsm is used for price conscious audience from base of pyramid. 180-200 gsm is for consumers who are ready to spend some extra bucks for quality. Above 220 is all for those who spend for quality. 220+ gsm sheets produces a feel that is incomparable. You can also make them reversible, as stains aren’t visible on the other side of fabric due to the thickness.

With the experience of 20 years, and a high spending on R&D, we have shortlisted some fabrics that have more value for money, making it easy for a new brand to choose.

1-Low cost 100% Cotton, 140-160 gsm

2-Low cost 97% Cotton 3% Spandex, 160-180 gsm

3-Fine quality 100% Cotton, 140-160 gsm

4-Fine Quality 95% Cotton 5% Spandex, 180-200 gsm

5-Supreme Quality Soft 100% Cotton, 200 gsm

6-Supreme Quality Soft 95% Cotton 5% Spandex, 250 gsm

7-Supreme Quality 100% Bamboo, 200 gsm

8-Fine quality 95% Bamboo 5% Spandex, 200 gsm

9-Supreme Quality 95% Bamboo 5% Spandex, 250-280 gsm

Contact Us for pricing difference of these above mentioned fabrics.

Color: Select from the ⇒ Color Chart

Print: You may design a print, especially for baby crib sheets; however, for regular large sizes, solid dyed can be the best bet.

Elastic: Elastic should also be durable if you are going for a good quality sheet. Select from provided samples

Design: Your creativity can work here. You may add something that is practical and user friendly e.g. Pocket, handles etc.

Packaging: From simple poly bag to adding stiffener, inlay card, cardboard box to same fabric bag, you may create an attractive yet low cost packaging.

How to Develop Packaging for your Bed Sheets

To Make it Attractive for Consumers

Below mentioned aspects are to be considered while developing a packaging

- It must safely deliver the product to the end consumer

- It must be attractive to trigger buying decision when a consumer see it in shelves or in pictures

- Cost Effectiveness-Value for Money

There are four option of materials you can play with

1-Plastic bags: Lowest Cost, Saves from dirt, transparent

2-Kraft Board boxes: High Cost-Environment Friendly-Recycled and Recyclable material

3-Canvas Bags: High Cost-Environment Friendly-Recycled and Recyclable material

4-Same Fabric Bags: Medium Cost- Environment Friendly- Recyclable Material-Let the Consumer see and feel the fabric without opening the packing

You may play with different designs, print colors and embroideries using above mentioned packaging materials.

Prototypes: A physical version of your brainstormed design will tell you a lot before going into market

Finalize it! Go for Production.

SELL BEDSHEETS, RECEIVE FEEDBACK & COMMUNICATE TO US

Knitted Bed Sheets are produced with Jersey-Honey Comb or Plaited Jersey. Knit fabrics are more durable, softer, and stronger than woven fabrics. They have high elasticity which makes it best for bed sheets. In the past, Jersey was only used for garments; however, their characteristics are making them popular in bedsheets as well. Their softness and ease to use is far higher than woven bed sheets. Jersey makes the bed sheets wrinkle free; you don’t need to worry about making the bed again and again

What are the characteristics of the available materials?

100% Polyester: considered the cheapest material. It is highly durable and washable. The strength of the yarn is much more than any natural fiber alternatives. Polyester yarn comes in different varieties. The use of thinner varieties with a higher number of filaments can make the fabric softer and more lustrous. However, polyester does not go well with the skin, it produces charge.

Cotton: one of the best options; Bed Sheets have direct contact with the skin and cotton goes very well with it. It is a healthy and Eco-friendly option as natural fibers are biodegradable. Cotton is expensive than polyester.

Combed Cotton: This is the superior quality of cotton. Its softness and durability is greater than carded cotton. It doesn’t change the shape after washing. Colorfastness is better than simple cotton. Bed Sheets made of Combed Cotton Jersey looks and feels great. The use of extra-fine thin combed cotton yarn produces a feel like velvet.

Bamboo: Bamboo is the best option among natural fibers. It is Softer, more Absorbent, more Durable, more Washable than cotton. Its color fastness is better than cotton. It goes very well with the skin, the same as cotton. However, it is expensive than even combed cotton. While designing a Jersey Knitted bedsheet, you may consider it if your decided price range allows you.